- Home

- Products

- Elementary

- Boride Powder

- 3D Printing Powder

- Sulfide Powder

- Oxide Powder

- Carbide powder

- Nitride Powder

- Silicide Powder

- Hydride Powder

- Telluride Powder

- Selenide Powder

- Stearic Acid Series

- Phosphide Powder

- Nanoparticles

- Metal Alloy

- MAX Phase

- Lithium Battery Anode

- Surfactant

- Molecular sieves

- Concrete Admixtures

- News

- Answers

- Contact

- About

How to improve nanoparticles to make them more superior nanomaterials

Jumble of nanoparticles

The heap of nanoparticles can be divided into 2 types: soft cluster and tough heap. Soft agglomeration is mostly brought on by the electrostatic force between bits and also van der Waals force. Due to the weak force, soft pile can pass some chemical methods.

The law or the application of power to remove; the formation of difficult cluster in enhancement to electrostatic forces and also van der Waals pressures, there are chemical bonds, so tough agglomerates are hard to ruin, require to take some unique approaches to regulate.

< img src="// ueeshop.ly200-cdn. com/u _ file/UPAI/UPAI779

/ 1907/photo/1661a376e4. png"/ > Schematic layout of agglomeration of nanoparticles Diffusion of nanoparticles One of the techniques to avoid the development of high-density, hard-block precipitates of nanoparticles is to minimize van der Waals attraction or communication between teams, to ensure that the primary fragments are not easily agglomerated to develop additional particles, therefore preventing more inter-atomic bonding. This leads to the formation of high-density, hard-blocked precipitates. The anti-agglomeration device of nanoparticles is split right into: (1) electrostatic stabilization (DLVO theory); (2) steric stablizing; (3) electrostatic steric stablizing.

Nanoparticle dispersion concept Electrostatic stabilization device (DLVO concept)

The electrostatic stabilization device, additionally called the electrical dual layer stablizing device, forms an electrical dual layer by adjusting the pH value to create a certain quantity of surface area charge on the surface of the fragment. The tourist attraction in between the bits is substantially reduced by the repulsive pressure between the electrical double layers, thus understanding the dispersion of the nanoparticles. The mechanism is shown as revealed in Figure 2.

< img src="// ueeshop.ly200-cdn. com/u _ file/UPAI/UPAI779

/ 1907/photo/1661a376e4. png"/ > Schematic layout of agglomeration of nanoparticles Diffusion of nanoparticles One of the techniques to avoid the development of high-density, hard-block precipitates of nanoparticles is to minimize van der Waals attraction or communication between teams, to ensure that the primary fragments are not easily agglomerated to develop additional particles, therefore preventing more inter-atomic bonding. This leads to the formation of high-density, hard-blocked precipitates. The anti-agglomeration device of nanoparticles is split right into: (1) electrostatic stabilization (DLVO theory); (2) steric stablizing; (3) electrostatic steric stablizing.

Nanoparticle dispersion concept Electrostatic stabilization device (DLVO concept)

The electrostatic stabilization device, additionally called the electrical dual layer stablizing device, forms an electrical dual layer by adjusting the pH value to create a certain quantity of surface area charge on the surface of the fragment. The tourist attraction in between the bits is substantially reduced by the repulsive pressure between the electrical double layers, thus understanding the dispersion of the nanoparticles. The mechanism is shown as revealed in Figure 2.

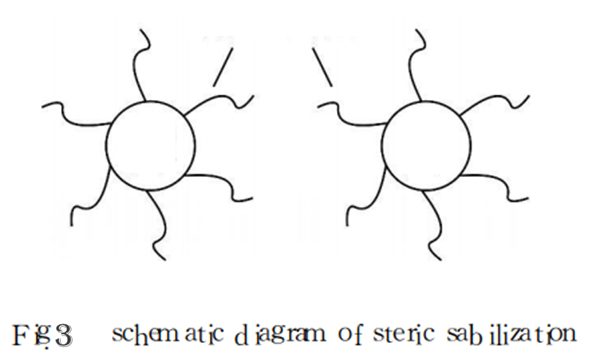

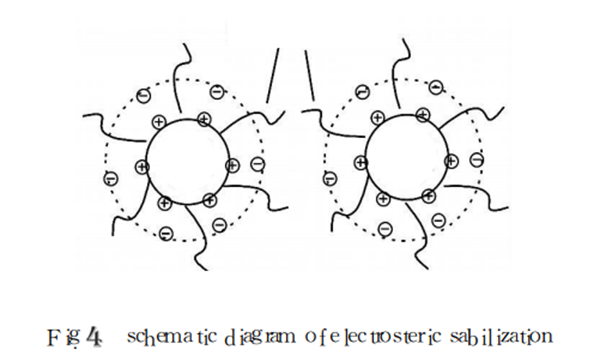

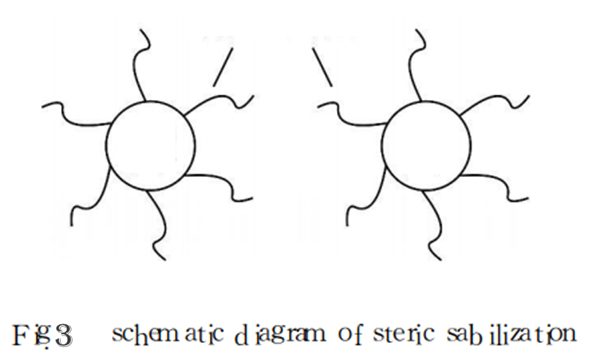

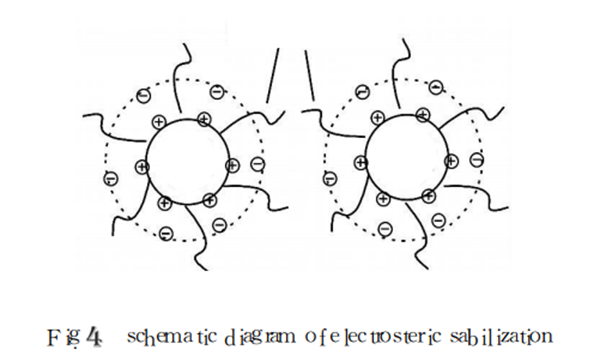

- < img src="// ueeshop.ly200-cdn. com/u _ file/UPAI/UPAI779/ 1907/photo/38c1a5ba33. png"/ > Stochastic stabilization system The steric stabilization device is to include a certain quantity of uncharged polymer substance to the suspension to adsorb it around the nanoparticles to create a microcell state, which causes repulsion between the fragments, therefore achieving the purpose of diffusion. The mechanism representation is displayed in Figure 4.

- Electrostatic steric stabilization mechanism

The pH worth of the polyelectrolyte maximizes the dissociation degree of the polyelectrolyte, so that the polyelectrolyte externally of the fragment gets to the saturated adsorption, and both together function to consistently spread the nanoparticles. The system diagram is displayed in Number 3.

< img src="// ueeshop.ly200-cdn.

com/u _ file/UPAI/UPAI779/ 1907/photo/ed7d9c96f4. png"/ > Nanoparticle dispersion method The diffusion of nanoparticles in the medium is usually split right into 3 stages: 1 liquid wetting the solid fragments; 2 dispersing the bigger accumulations into smaller sized fragments by exterior force; 3 maintaining the distributed bits, making certain that the powder particles remain in the fluid The phase remains evenly dispersed for a lengthy duration of time to stop the dispersed particles from re-aggregating. According to different diffusion devices, it can be divided right into mechanical activity technique as well as surface modification approach.

< img src="// ueeshop.ly200-cdn.

com/u _ file/UPAI/UPAI779/ 1907/photo/ed7d9c96f4. png"/ > Nanoparticle dispersion method The diffusion of nanoparticles in the medium is usually split right into 3 stages: 1 liquid wetting the solid fragments; 2 dispersing the bigger accumulations into smaller sized fragments by exterior force; 3 maintaining the distributed bits, making certain that the powder particles remain in the fluid The phase remains evenly dispersed for a lengthy duration of time to stop the dispersed particles from re-aggregating. According to different diffusion devices, it can be divided right into mechanical activity technique as well as surface modification approach.

- Mechanical action

- Surface area modification

- Surface area modification of nanoparticles by inorganic substances

- Surface alteration of nanoparticles by natural issue

< img src ="// ueeshop.ly200-cdn.

com/u _ file/UPAI/UPAI779/ 1907/photo/c845513ec8. png"/ > verdict The surface area adjustment technology of nanoparticles is an edge self-control very closely pertaining to numerous other techniques, including colloidal chemistry, organic chemistry, crystallography, nanomaterials, contemporary instrument evaluation and screening. The surface covering adjustment technology has been commonly made use of in the surface area adjustment of nanometers, and also the research causes this location also reveal that the surface area finishing innovation has an excellent development prospect. Nevertheless, the alteration mechanism, alteration method as well as tools, and also the adjustment impact characterization are still not best. Often times, the problem can not be addressed fundamentally, and also additional study is quickly required. Due to the substantial adjustments in the physical and chemical residential or commercial properties of the surface-treated particles, the development of nano surface area adjustment technology is considered an essential means of generating new products in the future. With the continuous research study and understanding of nano-particles, and also additionally exploration of the surface area modification of nano-powders, nano-technology will absolutely apply possible power in various fields and also will generate a great culture. Advantages as well as financial benefits.

< img src ="// ueeshop.ly200-cdn.

com/u _ file/UPAI/UPAI779/ 1907/photo/c845513ec8. png"/ > verdict The surface area adjustment technology of nanoparticles is an edge self-control very closely pertaining to numerous other techniques, including colloidal chemistry, organic chemistry, crystallography, nanomaterials, contemporary instrument evaluation and screening. The surface covering adjustment technology has been commonly made use of in the surface area adjustment of nanometers, and also the research causes this location also reveal that the surface area finishing innovation has an excellent development prospect. Nevertheless, the alteration mechanism, alteration method as well as tools, and also the adjustment impact characterization are still not best. Often times, the problem can not be addressed fundamentally, and also additional study is quickly required. Due to the substantial adjustments in the physical and chemical residential or commercial properties of the surface-treated particles, the development of nano surface area adjustment technology is considered an essential means of generating new products in the future. With the continuous research study and understanding of nano-particles, and also additionally exploration of the surface area modification of nano-powders, nano-technology will absolutely apply possible power in various fields and also will generate a great culture. Advantages as well as financial benefits.

Luoyang Tech Co., Ltd is a specialist Zinc Nanoparticles maker with over 12 years experience in chemical items r & d. If you are seeking excellent quality Zinc Nanoparticles, please feel free to call us as well as send out a query.

Inquiry us

PREVIOUS NEWS

The role of redispersible latex powder in mortar

NEXT NEWS

< img src="// ueeshop.ly200-cdn.

com/u _ file/UPAI/UPAI779/ 1907/photo/ed7d9c96f4. png"/ > Nanoparticle dispersion method The diffusion of nanoparticles in the medium is usually split right into 3 stages: 1 liquid wetting the solid fragments; 2 dispersing the bigger accumulations into smaller sized fragments by exterior force; 3 maintaining the distributed bits, making certain that the powder particles remain in the fluid The phase remains evenly dispersed for a lengthy duration of time to stop the dispersed particles from re-aggregating. According to different diffusion devices, it can be divided right into mechanical activity technique as well as surface modification approach.

< img src="// ueeshop.ly200-cdn.

com/u _ file/UPAI/UPAI779/ 1907/photo/ed7d9c96f4. png"/ > Nanoparticle dispersion method The diffusion of nanoparticles in the medium is usually split right into 3 stages: 1 liquid wetting the solid fragments; 2 dispersing the bigger accumulations into smaller sized fragments by exterior force; 3 maintaining the distributed bits, making certain that the powder particles remain in the fluid The phase remains evenly dispersed for a lengthy duration of time to stop the dispersed particles from re-aggregating. According to different diffusion devices, it can be divided right into mechanical activity technique as well as surface modification approach.

< img src ="// ueeshop.ly200-cdn.

com/u _ file/UPAI/UPAI779/ 1907/photo/c845513ec8. png"/ > verdict The surface area adjustment technology of nanoparticles is an edge self-control very closely pertaining to numerous other techniques, including colloidal chemistry, organic chemistry, crystallography, nanomaterials, contemporary instrument evaluation and screening. The surface covering adjustment technology has been commonly made use of in the surface area adjustment of nanometers, and also the research causes this location also reveal that the surface area finishing innovation has an excellent development prospect. Nevertheless, the alteration mechanism, alteration method as well as tools, and also the adjustment impact characterization are still not best. Often times, the problem can not be addressed fundamentally, and also additional study is quickly required. Due to the substantial adjustments in the physical and chemical residential or commercial properties of the surface-treated particles, the development of nano surface area adjustment technology is considered an essential means of generating new products in the future. With the continuous research study and understanding of nano-particles, and also additionally exploration of the surface area modification of nano-powders, nano-technology will absolutely apply possible power in various fields and also will generate a great culture. Advantages as well as financial benefits.

< img src ="// ueeshop.ly200-cdn.

com/u _ file/UPAI/UPAI779/ 1907/photo/c845513ec8. png"/ > verdict The surface area adjustment technology of nanoparticles is an edge self-control very closely pertaining to numerous other techniques, including colloidal chemistry, organic chemistry, crystallography, nanomaterials, contemporary instrument evaluation and screening. The surface covering adjustment technology has been commonly made use of in the surface area adjustment of nanometers, and also the research causes this location also reveal that the surface area finishing innovation has an excellent development prospect. Nevertheless, the alteration mechanism, alteration method as well as tools, and also the adjustment impact characterization are still not best. Often times, the problem can not be addressed fundamentally, and also additional study is quickly required. Due to the substantial adjustments in the physical and chemical residential or commercial properties of the surface-treated particles, the development of nano surface area adjustment technology is considered an essential means of generating new products in the future. With the continuous research study and understanding of nano-particles, and also additionally exploration of the surface area modification of nano-powders, nano-technology will absolutely apply possible power in various fields and also will generate a great culture. Advantages as well as financial benefits.